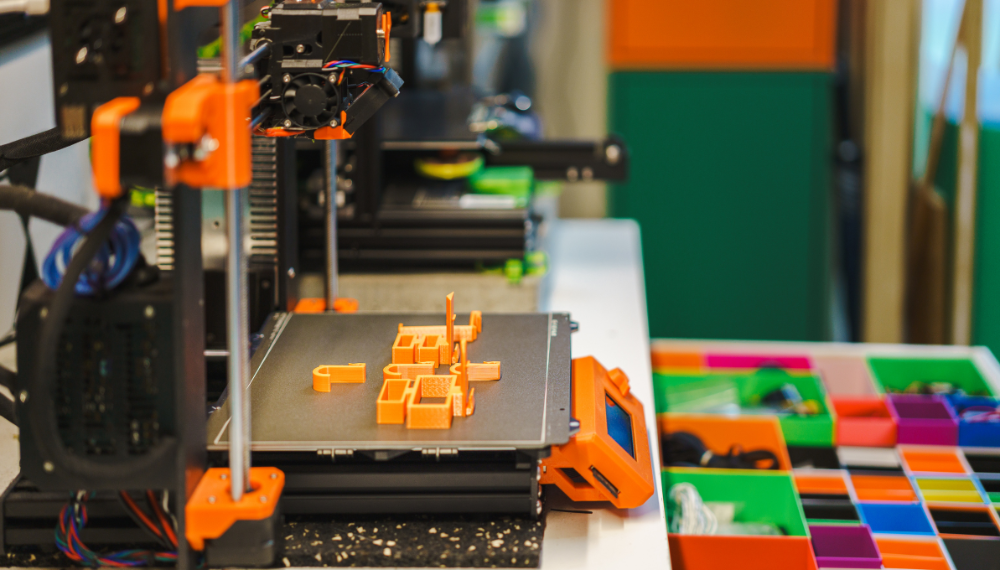

Advanced 3D Printing Techniques to Take Your Projects to the Next Level

Master advanced 3D printing techniques to elevate your projects with precision, creativity, and efficiency. Unlock new possibilities in modern manufacturing!

Yo, advanced 3D printing’s like the magic wand of modern engineering! With some nifty techniques and materials, you can take your projects higher than a kite. Let’s chat about some cool uses, the latest in polymer magic, and where metal 3D printing is heading.

Revolutionary Applications of 3D Printing

Think 3D printing’s just for school science projects? Nope! It’s totally shaking up industries. In aerospace, for example, folks are 3D printing serious gear, like those crazy turbine blades and fuel nozzles. The really neat bit? They’re built for mind-bending efficiency and performance (Xometry).

Here’s a peek at some jet-set parts:

| Component | Use |

|---|---|

| Turbine Blades | Zoomy Efficiency |

| Fuel Nozzles | Sizzling Combustion |

| Combustion Chambers | Pumped-up Performance |

Advancements in Polymer Materials

So, polymers are really stepping up their game. These super plastics are tougher than grandma’s old fruitcake, resistant to almost anything, and handle heat like a boss, all thanks to tech like Fused Deposition Modeling (FDM) (Xometry).

Check these out:

| Material | Benefit |

|---|---|

| High-Strength Polymers | Tough as Nails |

| Chemically Resistant Polymers | Endurance Personified |

| Thermally Stable Polymers | Heat Warriors |

New Frontiers in Metal Additive Manufacturing

Metal 3D printing is like the new kid everyone wants to hang with. It’s getting fancy, printing stuff like turbine blades and fuel nozzles that are light but still pack a punch in efficiency and performance (Xometry).

Here’s why it’s awesome:

| Component | Advantage |

|---|---|

| Turbine Blades | Featherweight Champs |

| Fuel Nozzles | Master Blasters |

| Combustion Chambers | Turbo Boosters |

Jumping on these 3D printing tricks can totally revamp your projects. Whether you’re in aerospace, making zippy cars, or inventing the next best thing, these tools will help you level up. So stay curious, keep experimenting, and watch your work skyrocket into the future!

Industries Getting a Boost From Advanced 3D Printing

Say hello to advanced 3D printing, the tech shaking things up and creating a buzz in various sectors. Some surprising areas you might not expect are reaping the benefits, and I’m gonna break it down for you.

Flight with a New Style

Over at aerospace headquarters, they’re doing more than dreaming of flying cars. Advanced 3D printing is in the cockpit, making vital plane parts like engine bits—turbine blades, fuel nozzles, and combustion chambers—snazzy and efficient. This tech buddies up with sci-fi-style designs that cut back on weight, helping planes sip fuel rather than guzzle it—a win for the environment and the industry’s wallet. For more insights and resources, check out trusted 3D printing sites to see how this tech is shaping the future of aerospace.

One big perk? Lighter aircraft with the same muscle punch. Thanks to 3D printing’s magic, these engineered wonders breeze through strict safety checks while trimming baggage (and emissions). Every savvy aerospace company is jumping on this tech to keep up and stay on regulators’ good sides.

| Component | Old School Costs | 3D Printing Tag |

|---|---|---|

| Turbine Blade | $10,000 | $7,000 |

| Fuel Nozzle | $5,000 | $3,500 |

| Combustion Chamber | $15,000 | $10,000 |

Bioprinting: Science Fiction or Fact?

Not too far off from Frankenstein, bioprinting is working the medical arena like a lab-coated maestro. Imagine printing functional tissue and organs with cells right from someone’s own body. It’s a wild thought, but it’s already sparking breakthroughs in how we approach things like tissue repair and drug testing.

We’re talking revolutionary. Create an organ that’s your exact cellular twin—less drama with rejections and dialed-down risks. Sure, it’s still growing up, but even at this stage, the benefits have doctors dreaming big.

| Application | Usual Costs | Bioprinting Bills |

|---|---|---|

| Tissue Repair | $50k – $100k | $20k – $50k |

| Drug Screening | $200,000 | $100,000 |

| Disease Modeling | $300,000 | $150,000 |

Manufacturing Goes Green

Printing in 3D is throwing manufacturing a lifeline to sustainability. It’s onboard for cutting waste, keeping up with circular economy ideas, and improving production oversight. Extra points for metal printing, too, as it crafts complex gizmos with finesse (Xometry).

The beauty of 3D? Use only what you need, scrapping old-school methods that had waste piles high enough to ski down. On top of that, recycling becomes a breeze, giving Mother Earth a much-needed break as well.

| Measure | Regular Methods | 3D Printing Deck |

|---|---|---|

| Material Waste (%) | 20 – 30 | 1 – 5 |

| Energy Use | High | Low |

| Carbon Footprint | High | Low |

These sectors are just a taste of who is hitching a ride on the advanced 3D printing express. With tech marching forward at light speed, the horizon’s bound to get a little brighter with more amazing breakthroughs.

3D Printing Versus Traditional Manufacturing

Evolution of 3D Printing

Back in 1983, a guy named Chuck Hull kicked off 3D printing and turned it into a cool way to make prototypes real quick. Fast forward, and this tech’s become a solid way to whip up a variety of stuff. Nowadays, with 3D printing in the mix, folks have a wild amount of freedom to get creative with design, building incredibly detailed things. It’s like an artist’s dream come true, letting you make custom, small-batch parts without breaking the bank. Thanks to advancements, starting your own project or business isn’t as pricey as it used to be (Xometry).

Comparing Traditional and Additive Manufacturing

Let’s toss traditional manufacturing and 3D printing side by side and see how they stack up:

| Criteria | Traditional Manufacturing | 3D Printing (Additive Manufacturing) |

|---|---|---|

| Material Use | Chop it off a larger block (subtractive) | Layer by layer (additive) |

| Waste | Mount Everest levels | Way less, only what you need |

| Design Flexibility | Kind of boxed in | Sky’s the limit |

| Cost Benefits | Best for mass-producing boatloads of stuff | Great for one-offs or small runs |

| Customization | Costs an arm and a leg because of molds and all | Cheap and cheerful customization |

| Materials | Loads of choices (wood, steel, plastic) | More and more materials getting added, including cool metals |

| Industries | Big stuff (like couches and toys) | Niche stuff (think robots and rockets) |

Check out more at Xometry.

Rapid Tooling: Bridging the Gap

Rapid tooling is like finding the sweet spot between old-school and new-school ways of making things. It mainly focuses on low-volume injection molding, using stuff like 3D printing and CNC machines to spit out parts quickly.

Here’s why rapid tooling’s the bee’s knees:

- Speed: It’s like taking the express lane compared to the snail pace of traditional ways.

- Cost-Effectiveness: Save the big bucks upfront, especially great when you’re not making a gazillion items.

- Flexibility: Perfect for trying out something new in small batches or just needing something tailor-made.

Using rapid tooling, you snag the precision and range of materials from traditional methods—minus the wallet-draining costs and long waits. It’s a top pick for small businesses and budding entrepreneurs itching to get their products out there without emptying their pockets (Xometry).

Materials Changing the Game in 3D Printing

When I chat about the latest in 3D printing, I can’t help but geek out over the amazing stuff being used to whip up some seriously cool custom products. Let me take you through some of these top-notch materials that are shaking things up in the scene.

Super Cool Polymers

Polymers these days are a big deal in 3D printing. Folks are working hard to come up with materials that don’t just look good but can also take a beating and keep going. The focus is on making them do well under heat and chemical conditions—especially for Fused Deposition Modeling (FDM) 3D printing. If you’re on the hunt for something that can take on any task, these polymers have got your back.

Prime Examples of Super Polymers

- PEEK (Polyether Ether Ketone)

- PEKK (Polyetherketoneketone)

- PEI (Ultem)

These hot-shot polymers are favorites in areas like medicine and industry ’cause they can handle extreme temperatures and are tough as nails.

| Polymer | Melting Temperature (°C) | Uses |

|---|---|---|

| PEEK | 343 | Implants in healthcare, stuff going to space |

| PEKK | 360 | Tough mechanical parts |

| PEI (Ultem) | 217 | Protecting electrical equipment, cars |

Metals on the Cutting Edge

With metal 3D printing, some new alloys are taking the spotlight. They’re stronger and can handle heavy-duty tasks without getting rusty. Handy, right?

Best of the Metal Bunch

- Titanium Alloys

- Aluminum Alloys

- Nickel Alloys

Titanium’s a fan favorite with its just-right mix of strength and lightweight vibes, making it a go-to for planes and medical gear.

| Metal | Traits | Everyday Jobs |

|---|---|---|

| Titanium | Light, sturdy, no rust | Planes, medical gadgets |

| Aluminum | Strong, light, easy to recycle | Cars, planes |

| Nickel | Stands up to rust, likes the heat | Big factory machines, sea stuff |

Composites of the Future

Got a need for something that’s all about being strong and feather-light? Composites are your best bet. These bad boys often pack fibers like carbon or glass mixed in a plastic base.

Types of Leading Composites

- Carbon Fiber Composites

- Glass Fiber Composites

- Kevlar Composites

Composites are the go-to choice when you need something light and sturdy, making them ideal for cars and planes.

| Composite | Fiber Type | What It Offers |

|---|---|---|

| Carbon Fiber Composite | Carbon | Crazy strong, keeps its shape |

| Glass Fiber Composite | Glass | Durable, budget-friendly |

| Kevlar Composite | Kevlar | Super tough, stands up to impacts |

Jumping on board with these advanced materials in your 3D projects means you’re cooking up high-quality, creative, and long-lasting stuff that’ll make people take notice. Whether it’s for your new biz bucket list or catering unique needs for clientele, these materials open up a whole world of possibilities.